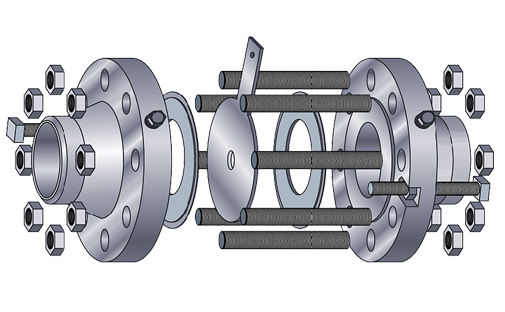

Carbon Steel A105 Socket weld Flanges, A105 Long Weld Neck Flanges Stockist, A105 SORF Flanges, ASME SA105 Carbon Steel Forged Flanges, ASTM A105 RTJ Flanges Supplier in Mumbai, India.

Depending at the alloying detail delivered, the properties can range significantly. Carbon Steel ASTM A105 Weld Neck Flanges comes right all the way down to the necessities for the software to pick the maximum appropriate cost-powerful option. Chromium is the defining alloying detail in chrome steel. The passive layer of chromium oxide in conjunction in company of the safety of the floor additionally blocks oxygen diffusion into the steel saving the steel’s inner shape from corrosion. Chromium oxide ions also are comparable in length to metallic molecules ensuing in a sturdy bond among the two. This allows the oxide ions to stay strongly connected to the floor below normal working conditions.

However, including even extra chromium is not unusual place for an accelerated corrosion resistance. Chromium content in ASME SA 105 Carbon Steel Reducing Flanges additionally acts as a ferrite stabilizer inflicting the formation of the ferrite microstructure within the alloy. Nickel is delivered in chrome steel to in addition enhance corrosion resistance. It is likewise an austenite stabilizer, prompting the formation of austenite. Adding of nickel in this steel obtains a totally austenitic shape which presents first-rate welding properties. Further growing the nickel percent brings approximately better properties for work cap-potential and corrosion resistance.

Material Specification Chart of Carbon Steel A105 Flanges

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Carbon Steel A105 Flanges Manufacturing Standards

| American Standard | Standard Code | ANSI ASME SA105 | ANSI ASME B16.5 | ASME – B 16.47 | ASME – B 16.36 | ||

|---|---|---|---|---|---|---|---|

| Standard Name | Forged Flanges | Slip on flange, Welding neck flange, Blind flange, Threaded flange, Lap joint flange, RTJ flange | Welding neck flange, Blind flange | Welding neck flange Slip on flange | |||

| German Standard | DIN 2527 | DIN 2573 / 2576 | DIN 2673 | DIN 2641 / 2642 | DIN 28115 | DIN PN10, PN16 | DIN PN20, PN25 |

| Blind Flanges, BLRF | Flat Flange for Welding (Slip On) | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) | Lapped / Loose (Lap Joint) Flanges Plain Collars | Long Neck Welding Flanges | PN10 Flanges, DIN PN 10 Flanges, PN16 Flange | PN20 Flanges, DIN PN 25 Flanges | |

| Japanese Standard | JIS B2220 | JIS B2291 | JIS 5K, 10K | JIS 16K, 20K | JIS 30K, 40K | ||

| Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | 5K SORF Flanges, 10K SOFF Flanges | 16K Blind Flanges, 20K BLRF Flanges | 30K Slip on Flanges, 40K Blind Flanges | |||

| Italian Standard | UNI FLANGES | ||||||

| Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) | |||||||

| British Standard | BS 10 Table D | BS 10 Table E | BS 10 Table F | BS 10 Table H | |||

| BS 10 Table D Flanges, Table D Pipe Flange | BS 10 Table E Flanges, Table E Pipe Flange | BS 10 Table E Flanges, Table E Flanges | BS 10 Table E Flanges, Table E Pipe Flanges |

Manufacturing Standards / Pressure Rating

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN A105 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Various Types Of Carbon Steel A105 Flanges

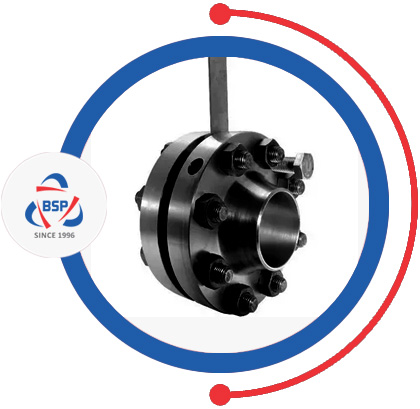

- ASTM A105 Carbon Steel Socket weld Flanges

- ASME SA105 Carbon Steel SWRF Flanges

- Carbon Steel A105 Socket weld Flange

- CS A105 Socket weld Flanges

- A105 Carbon Steel Socket weld Flanges

- Carbon Steel A105 SWRF Flanges

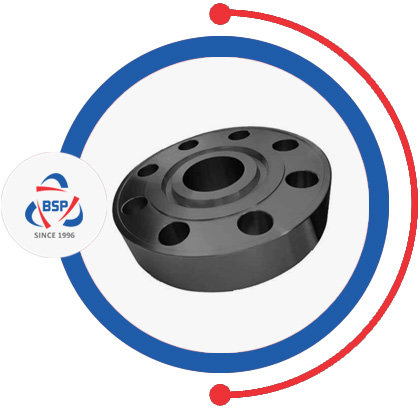

- Carbon Steel A105 Lapped Joint Flanges

- Carbon Steel A105 Lap Joint Flanges

- ASME SA105 Carbon Steel Lapped Joint Flanges

- Carbon Steel A105 LJ Flanges

- CS A105 Lap Joint Flange

- ASTM A105 Carbon Steel Lap Joint Flanges

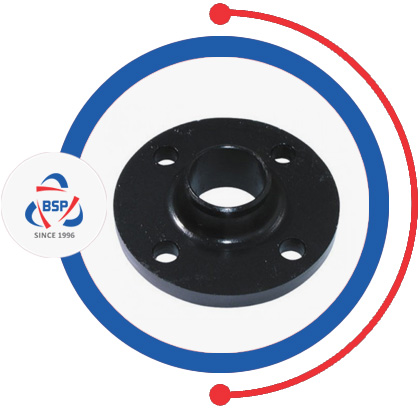

- Carbon Steel A105 Slip on Flange

- CS A105 Slip on Flanges

- ASTM A105 Carbon Steel Slip on Flanges

- ASME SA105 Carbon Steel SORF Flanges

- Carbon Steel A105 SORF Flanges

- A105 Carbon Steel Slip on Flanges

- Carbon Steel A105 Forged Flanges

- ASTM A105 Carbon Steel Forged Flanges

- CS A105 Forged Flanges

- ASME SA105 Carbon Steel Forged Flanges

- A105 Carbon Steel Forged Flange

- Carbon Steel ASTM A105 Forged Flanges

- Carbon Steel A105 Orifice Flange

- CS A105 Orifice Flanges

- A105 Carbon Steel Orifice Flanges

- ASTM A105 Carbon Steel Orifice Flanges

- Carbon Steel ASTM A105 Orifice Flanges

- ASME SA105 Carbon Steel Orifice Flanges

- ASME SA105 Carbon Steel BLRF Flanges

- CS A105 Blind Flanges

- Carbon Steel ASTM A105 BLRF Flanges

- Carbon ASTM A105 Blind Flange

- ASTM A105 Carbon Steel Blind Flanges

- ASME SA105 Carbon Steel WNRF Flanges

- Carbon Steel A105 Welding Neck Flanges

- ASTM A105 Carbon Steel Weld Neck Flanges

- CS A105 Welding Neck Flange

- Carbon Steel A105 WNRF Flanges

- Carbon Steel ASTM A105 Weld Neck Flanges

- ASME SA105 Carbon Steel Reducing Flanges

- ASTM A105 Carbon Steel Reducing Flanges

- CS A105 Reducing Flanges

- Carbon Steel ASTM A105 Reducing Flanges

- A105 Carbon Steel Reducing Flanges

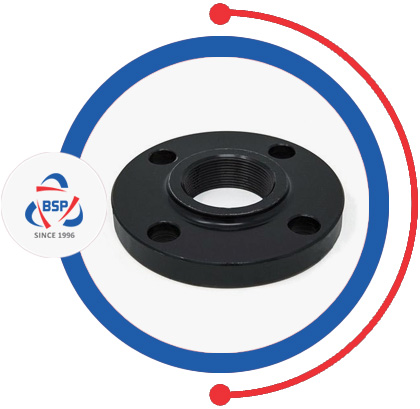

- Carbon Steel A105 Screwed Flanges

- Carbon Steel A105 Threaded Flanges

- ASTM A105 Carbon Steel Threaded Flanges

- ASME SA105 Carbon Steel Screwed Flanges

- Carbon Steel ASTM A105 Threaded Flanges

- A105 Carbon Steel Threaded Flange

- Carbon Steel A105 Long Weld Neck Flange

- ASME SA105 Carbon Steel LWN Flanges

- CS A105 Long Weld Neck Flanges

- ASTM A105 Carbon Steel Long Weld Neck Flanges

- Carbon Steel ASTM A105 LWN Flanges

- A105 Carbon Steel Long Weld Neck Flanges

- ASME SA105 Carbon Steel Spectacle Blind Flanges

- Carbon Steel A105 Spectacle Blind Flange

- CS A105 Spectacle Blind Flanges

- ASTM A105 Carbon Steel Spectacle Blind Flanges

- Carbon Steel ASTM A105 Spectacle Blind Flanges

- A105 Carbon Steel Spectacle Blind Flanges

- Carbon Steel A105 Ring Type Joint Flanges

- CS A105 Ring Type Joint Flange

- ASTM A105 Carbon Steel RTJ Flanges

- Carbon Steel ASTM A105 RTJ Flanges

- ASME SA105 Carbon Steel RTJ Flanges

- A105 Carbon Steel Ring Type Joint Flanges

View Size Table Of Carbon Steel A105 Pipe Flanges, We have Global sales network for Carbon Steel A105 SORF Flanges, Wide Stockist Of Carbon Steel A105 BLRF Flanges, Raised Face, Flat Face Flanges In India.

Check available Sizes of ASME SA105 Carbon Steel Pipe Flanges, Ask For Ready Stock of Carbon Steel A105 Male & Female Flanges in Mumbai, India.

BAGODA

Quick ContactSchedule / Class of Carbon Steel A105 Flanges

| Flange Schedule/Class | Flange Connection Type | Pipe Size – Pipe Flanges | Max. Pressure |

|---|---|---|---|

| ASME B16.5 Class 150 | FNPT | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 1/2″ | 275 psi |

| ASME B16.5 Class 150 | Welded | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | FNPT | 3/4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 3/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 1-1/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 1-1/2″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | 2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 2-1/2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 3″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | 4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 4″ | 275 psi |

| ASME B16.5 Class 300 | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | FNPT | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 4″ | 720 psi |

Pressure Rating Of Carbon Steel A105 Flanges

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Size Chart Of Carbon Steel A105 Flange

| Nominal Pipe Size | Outside Diameter of Flanges | Thickness of Flanges | Diameter of Raised Face | Diameter of Hub at Base | Length Thru Hub | Diameter or Bore | Diameter of Hub at Bevel | Radius of Fillet | Depth of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding Neck | Slip-On Threaded Socket | Lap Joint | Slip-on Socket | Lap Joint | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Weight Chart Of Carbon Steel A105 Flanges

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

| 1/2" | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2" | 0.4 | 0.9 |

| 3/4" | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2" | 0.7 | 1.5 |

| 1" | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2" | 0.8 | 1.8 |

| 1-1/4" | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2" | 1.2 | 2.6 |

| 1-1/2" | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2" | 1.5 | 3.3 |

| 2" | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8" | 2.3 | 5.1 |

| 2-1/2" | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8" | 3.7 | 8.1 |

| 3" | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8" | 4.1 | 9 |

| 3-1/2" | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8" | 5.1 | 11.2 |

| 4" | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8" | 5.9 | 13 |

| 5" | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4" | 7 | 15.4 |

| 6" | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4" | 8.4 | 18.5 |

| 8" | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4" | 13 | 28.6 |

| 10" | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8" | 18 | 39.5 |

| 12" | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8" | 29 | 64 |

| 14" | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1" | 39 | 86 |

| 16" | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1" | 47 | 103 |

| 18" | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8" | 57 | 126 |

| 20" | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8" | 76 | 167 |

| 24" | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4" | 97 | 214 |

Ready Stock Carbon Steel A105 Flanges

- Carbon Steel A105 Blind Flanges Supplier in Mumbai

- 6 Inch Carbon Steel A105 Pipe Flanges

- ANSI B16.5 Carbon Steel A105 Male & Female Flanges

- Carbon Steel A105 EN 1092-1 Flange

- Carbon Steel A105 Welding Neck Flanges

- Carbon Steel A105 Blind Flange

- ASTM A105 Carbon Steel SORF Flange

- ASTM A105 Carbon Steel Expander Flanges

- Carbon Steel A105 Raised Face Flanges Exporter

- Carbon Steel A105 Orifice Flanges

- Carbon Steel A105 Loose Flanges

- CaS A105 Flanges

- Carbon Steel A105 BS 4504 Flanges

- Carbon Steel A105 Class 2500 Flange

- Carbon Steel A105 Lap Joint Flanges

- ANSI B16.5 Carbon Steel A105 PN16 Flanges

- 3 inch CS A105 Welding Neck 300 LBS Flange

- Carbon Steel A105 Large Diameter Flanges

- Carbon Steel A105 Screwed Flanges

- Carbon Steel A105 Tongue & Groove Flanges

- Carbon Steel A105 Flat Flanges

- Carbon Steel A105 AWWA C207 Flange Stockist

- Carbon Steel A105 Slip On Flanges Distributor

- Class 150 Carbon Steel A105 Pipe Flange

- ASME B16.5 CS A105 Spectacle Blind Flanges

- Carbon Steel A105 SWRF Flange

- Carbon Steel A105 JIS B2220 Flange

- A105 Carbon Steel RTJ Flanges Manufacturer

- Carbon Steel A105 BS 4504 Flanges

- Carbon Steel ASTM A105 BLRF Flange

- ASME B16.5 Carbon Steel A105 Slip on Flanges

- Carbon Steel A105 BLRF Flange

- Carbon Steel A105 Long Weld Neck Flanges

- Carbon Steel DIN 2566 PN10 Flanges Stockholder

- ASME SA105 Carbon Steel Forged Flanges

- Carbon Steel JIS B2220 Flange

- Carbon Steel A105 WNRF Flange

- Carbon Steel A105 Reducing Flanges

- Carbon Steel A105 JIS B2220 Flange

- Carbon Steel A105 Paddle Spacer Flanges

- Carbon Steel A105 Square Flanges

- Carbon Steel A105 High Hub Blind Flanges

- ASTM A105 Carbon Steel Socket weld Flanges

- Carbon Steel Lapped Joint Flanges

- Carbon Steel A105 Flanges

- Carbon Steel A105 DN150 PN16 Flange

- Carbon Steel A105 Threaded Flanges

- ASTM A105 Carbon Steel Plate Flanges

- Carbon Steel Flanges Manufacturer

- Carbon Steel A105 Ring Type Joint Flanges

- Carbon Steel A105 Pipe Flanges

- DIN Carbon Steel Pipe Flanges

Carbon Steel A105 Flanges Chemical Composition

| Element | Composition %, Note C |

|---|---|

| Carbon | .35 max |

| Manganese | .60-1.05 |

| Phosphorus | .035 max |

| Sulfur | .040 max |

| Silicon | .10-35 |

| Copper | .40 max, note A |

| Nickel | .40 max, note A |

| Chromium | .30 max, note A,B |

| Molybdenum | .12 max, note A,B |

| Vanadium | .08 max, note A |

| Note A – The sum of copper, nickel, chromium, molybdenum and vanadium shall not exceed 1.00% Note B – The sum of chromium and molybdenum shall not exceed .32% Note C – for each reduction of 0.01% below the specified carbon maximum (.35%), an increase of .06% manganese above the specified maximum (1.05%) will be permitted up to a maximum of 1.65% |

|