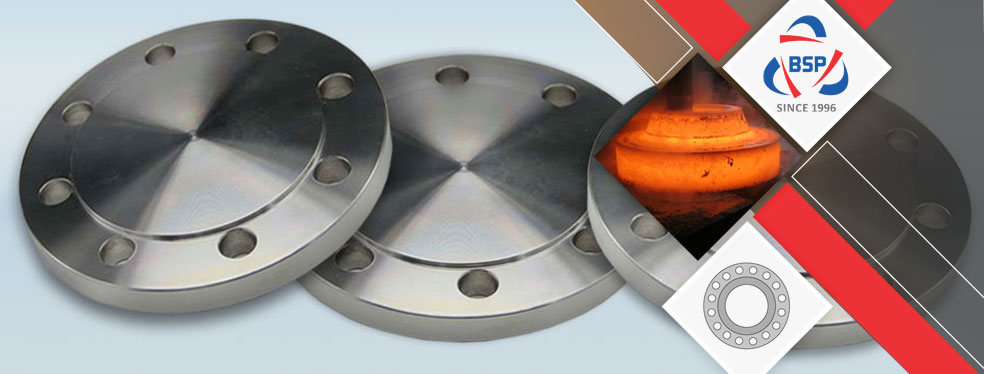

Inconel Raised Face Blind Flange, Stainless Steel Blind Flange, Alloy Steel Blind Flange, Hastelloy Blind Raised Face Flanges, Carbon Steel Blind Flanges, ANSI B16.5 BLRF Flanges Dealer, Class 150 Alloy Steel Blind Flanges, SS BLRF Stockist, Nickel Alloy Blind Plate Flanges, JIS 5K Blind Flanges Supplier in Mumbai, India.

It is an alloy with moderate strength and excellent resistance to oxidation and carburization at expanded temperatures. It is mainly beneficial for excessive-temperature device within the petrochemical enterprise due to the fact the alloy does now no longer shape the embrittling sigma segment after long term publicity at 1200 Degree F (649 Degree C). Excellent resistance to chloride stress-corrosion cracking is any other vital feature. Monel Alloy Blind Flanges is a solution warmth treated (2100 Degree F / 1150 Degree C), controlled-carbon model of this alloy with advanced extended temperature properties. It has advanced creep and stress-rupture traits within the 1100 Degree F (593 Degree C) to 1800 Degree F (982 Degree C) temperature variety.

Typical applications are - Heat exchangers and procedure piping; carburizing furniture and retorts; furnace additives; electric powered variety heating-detail sheathing; extruded tubing for ethylene and steam methane reforming furnaces; ammonia effluent coolers.The alloy has excessive yield strength and creep resistance at temperatures to approximately 1110 Degree F (600 Degree C). It is an alloy containing titanium and aluminum for precipitation hardening and molybdenum for solid-solution strengthening. Hastelloy Alloy Blind Flanges is much like other alloys however with advanced resistance to aqueous corrosion. Although now no longer completely immune to stress-corrosion cracking in boiling magnesium chloride, it has properly resistance in impartial chloride media.

Specification Chart of Blind Flanges

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ASME Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ASME B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most Common Types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove |

| Special design | As per your drawing |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of | ASME DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Uses & Application |

|

Material Grades of Blind Flanges

| Stainless Steel Blind Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel Blind Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel Blind Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium Blind Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Blind Flanges | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Blind Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Inconel Blind Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Class 150 Blind Flanges |

| Hastelloy Blind Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel Blind Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Blind Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Blind Flanges | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Alloy Blind Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex Steel Blind Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex Blind Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy Blind Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 SMO Blind Flanges | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Blind Flanges | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Brass Blind Flanges | 3602 / 2604 / H59 / H62 / etc. |

| Other Blind Flanges material | Tin bronze, Alumunum bronze, Lead bronze |

View Thickness Table Of ASME B16.5 Class 150, Class 300 And Class 600 Blind Flange, We have Global sales network for BLRF Flanges, Wide Stockist Of Blind Raised Face Flanges In India.

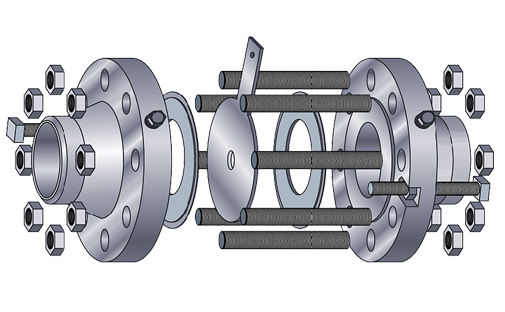

Dimensions of Blind Flanges

| ANSI/ASME/ASA B16.5 150lb/sq.in. Flanges SO-RF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2" | 88,9 | 11,1 | 34,9 | 30,2 | 22,3 | 15,9 | 60,3 | 4 | 15,9 | 0,400 |

| 3/4" | 98,4 | 12,7 | 42,9 | 38,1 | 27,7 | 15,9 | 69,8 | 4 | 15,9 | 0,700 |

| 1" | 107,9 | 14,3 | 50,8 | 49,2 | 34,5 | 17,5 | 79,4 | 4 | 15,9 | 0,800 |

| 1 1/4" | 117,5 | 15,9 | 63,5 | 58,8 | 43,2 | 20,6 | 88,9 | 4 | 15,9 | 1,100 |

| 1 1/2" | 127,0 | 17,5 | 73,0 | 65,1 | 49,5 | 22,2 | 98,4 | 4 | 15,9 | 1,400 |

| 2" | 152,4 | 19,0 | 92,1 | 77,8 | 62,0 | 25,4 | 120,6 | 4 | 19,0 | 2,200 |

| 2 1/2" | 177,8 | 22,2 | 104,8 | 90,5 | 74,7 | 28,6 | 139,7 | 4 | 19,0 | 3,600 |

| 3" | 190,5 | 23,8 | 127,0 | 107,9 | 90,7 | 30,2 | 152,4 | 4 | 19,0 | 4,100 |

| 3 1/2" | 215,9 | 23,8 | 139,7 | 122,2 | 103,4 | 31,7 | 177,8 | 8 | 19,0 | 5,200 |

| 4" | 228,6 | 23,8 | 157,2 | 134,9 | 116,1 | 33,3 | 190,5 | 8 | 19,0 | 5,600 |

| 5" | 254,0 | 23,8 | 185,7 | 163,6 | 143,8 | 36,5 | 215,9 | 8 | 22,2 | 6,300 |

| 6" | 279,4 | 25,4 | 215,9 | 192,1 | 170,7 | 39,7 | 241,3 | 8 | 22,2 | 7,500 |

| 8" | 342,9 | 28,6 | 269,9 | 246,1 | 221,5 | 44,4 | 298,4 | 8 | 22,2 | 12,600 |

| 10" | 406,4 | 30,2 | 323,8 | 304,8 | 276,3 | 49,2 | 361,9 | 12 | 25,4 | 18,500 |

| 12" | 482,6 | 31,7 | 381,0 | 365,1 | 327,1 | 55,6 | 431,8 | 12 | 25,5 | 28,000 |

| 14" | 533,4 | 34,9 | 412,7 | 400,0 | 359,1 | 57,1 | 476,2 | 12 | 28,6 | 36,000 |

| 16" | 596,9 | 36,5 | 469,9 | 457,2 | 410,5 | 63,5 | 539,7 | 16 | 28,6 | 46,000 |

| 18" | 635,0 | 39,7 | 533,4 | 504,8 | 461,8 | 68,3 | 577,8 | 16 | 31,7 | 50,000 |

| 20" | 698,5 | 42,9 | 584,2 | 558,8 | 513,1 | 73,0 | 635,0 | 20 | 31,7 | 64,000 |

| 22" | 749,3 | 46,0 | 641,2 | 609,6 | 564,4 | 79,4 | 692,1 | 20 | 34,9 | 72,000 |

| 24" | 812,8 | 47,6 | 692,1 | 663,6 | 615,9 | 82,5 | 749,3 | 20 | 34,9 | 89,000 |

| ANSI/ASME/ASA B16.5 600lb/sq.in. Flanges WN-RF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,800 |

| 3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,400 |

| 1" | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,600 |

| 1 1/4" | 133,3 | 20,6 | 63,5 | 63,5 | 43,2 | 28,6 | 98,4 | 4 | 19,0 | 2,100 |

| 1 1/2" | 155,6 | 22,2 | 73,0 | 69,8 | 49,5 | 31,7 | 114,3 | 4 | 22,2 | 3,100 |

| 2" | 165,1 | 25,4 | 92,1 | 84,1 | 62,0 | 36,5 | 127,0 | 8 | 19,0 | 3,700 |

| 2 1/2" | 190,5 | 28,6 | 104,8 | 100,0 | 74,7 | 41,3 | 149,2 | 8 | 22,2 | 5,400 |

| 3" | 209,5 | 31,7 | 127,0 | 117,5 | 90,7 | 46,0 | 168,3 | 8 | 22,2 | 7,300 |

| 3 1/2" | 228,6 | 34,9 | 139,7 | 133,3 | 103,4 | 49,2 | 184,1 | 8 | 25,4 | 8,900 |

| 4" | 273,0 | 38,1 | 157,2 | 152,4 | 116,1 | 54,0 | 215,9 | 8 | 25,4 | 11,800 |

| 5" | 330,2 | 44,4 | 185,7 | 188,9 | 143,8 | 60,3 | 266,7 | 8 | 28,6 | 24,500 |

| 6" | 355,6 | 47,6 | 215,9 | 222,2 | 170,7 | 66,7 | 292,1 | 12 | 28,6 | 29,500 |

| 8" | 419,1 | 55,6 | 269,9 | 273,0 | 221,5 | 76,2 | 349,2 | 12 | 31,7 | 43,000 |

| 10" | 508,0 | 63,5 | 323,8 | 342,8 | 276,3 | 85,7 | 431,8 | 16 | 34,9 | 70,000 |

| 12" | 558,8 | 66,7 | 381,0 | 400,0 | 327,1 | 92,1 | 488,9 | 20 | 34,9 | 86,000 |

| 14" | 603,2 | 69,8 | 412,7 | 431,8 | 359,1 | 93,7 | 527,0 | 20 | 38,1 | 100,000 |

| 16" | 685,8 | 76,2 | 469,9 | 495,3 | 410,5 | 106,4 | 603,2 | 20 | 41,3 | 142,000 |

| 18" | 742,9 | 82,5 | 533,4 | 546,1 | 461,8 | 117,5 | 654,0 | 20 | 44,4 | 175,000 |

| 20" | 812,8 | 88,9 | 584,2 | 609,6 | 513,1 | 127,0 | 723,9 | 24 | 44,4 | 232,000 |

| 22" | 869,9 | 95,2 | 641,2 | 666,7 | 564,4 | 133,3 | 777,9 | 24 | 47,6 | 292,000 |

| 24" | 939,8 | 101,6 | 692,1 | 717,5 | 615,9 | 139,7 | 838,2 | 24 | 50,8 | 330,000 |

ASME B16.5 Blind Flange Weight Chart

| Rated Diameter | O.D. of Pipe | Flange Parameter | Neck Size | Size of R.F. | Bolts | Approx. Weight | |||||||

| DN | d1 | D | d5 | b | k | h | d3 | r | d4 | f | No. of holes |

d2 | KG |

| 10 | 17.2 | 90 | 17.7 | 14 | 60 | 20 | 30 | 4 | 40 | 2 | 4 | 14 | 0.56 |

| 15 | 21.3 | 95 | 22 | 14 | 65 | 20 | 35 | 4 | 45 | 2 | 4 | 14 | 0.62 |

| 20 | 26.9 | 105 | 27.6 | 16 | 75 | 24 | 45 | 4 | 58 | 2 | 4 | 14 | 0.91 |

| 25 | 33.7 | 115 | 34.4 | 16 | 85 | 24 | 52 | 5 | 68 | 2 | 4 | 14 | 1.09 |

| 32 | 42.4 | 140 | 43.1 | 16 | 100 | 26 | 60 | 5 | 78 | 2 | 4 | 18 | 1.58 |

| 40 | 48.3 | 150 | 49 | 16 | 110 | 26 | 70 | 5 | 88 | 3 | 4 | 18 | 1.76 |

| 50 | 60.3 | 165 | 61.1 | 18 | 125 | 28 | 85 | 5 | 102 | 3 | 4 | 18 | 2.39 |

| 65 | 76.1 | 185 | 77.1 | 18 | 145 | 32 | 105 | 5 | 122 | 3 | 4 | 18 | 3.1 |

| 80 | 88.9 | 200 | 90.3 | 20 | 160 | 34 | 118 | 5 | 138 | 3 | 8 | 18 | 3.77 |

| 100 | 114.3 | 220 | 115.9 | 20 | 180 | 38 | 140 | 5 | 158 | 3 | 8 | 18 | 4.29 |

| 125 | 139.7 | 250 | 141.6 | 22 | 210 | 40 | 168 | 5 | 188 | 3 | 8 | 18 | 5.86 |

| 150 | 168.3 | 285 | 170.5 | 22 | 240 | 44 | 196 | 5 | 212 | 3 | 8 | 22 | 7.22 |

| 175 | 193.7 | 315 | 196.1 | 24 | 270 | 44 | 224 | 6 | 242 | 3 | 8 | 22 | 9.18 |

| 200 | 219.4 | 340 | 222 | 24 | 295 | 44 | 247 | 6 | 268 | 3 | 8 | 22 | 9.95 |

| 250 | 273 | 395 | 276 | 26 | 350 | 46 | 300 | 6 | 320 | 3 | 12 | 22 | 12.69 |

| 300 | 323.9 | 445 | 327 | 26 | 400 | 46 | 352 | 6 | 370 | 4 | 12 | 22 | 14.4 |

| 350 | 355.6 | 505 | 359 | 26 | 460 | 53 | 398 | 10 | 430 | 4 | 16 | 22 | 22.36 |

| 400 | 406.4 | 565 | 410 | 26 | 515 | 57 | 448 | 10 | 482 | 4 | 16 | 26 | 26.85 |

| 450 | 457 | 615 | 461 | 28 | 565 | 62 | 502 | 10 | 532 | 4 | 20 | 26 | 32.53 |

| 500 | 508 | 670 | 512 | 28 | 620 | 67 | 552 | 10 | 585 | 4 | 20 | 26 | 37.84 |

| 600 | 610 | 780 | 614 | 28 | 725 | 75 | 658 | 10 | 685 | 5 | 20 | 30 | 49.32 |

| 700 | 711 | 895 | 716 | 30 | 840 | 77 | 760 | 10 | 800 | 5 | 24 | 30 | 63.86 |

| 800 | 813 | 1015 | 818 | 32 | 950 | 84 | 864 | 10 | 905 | 5 | 24 | 33 | 85.19 |

| 900 | 914 | 1115 | 920 | 34 | 1050 | 88 | 969 | 10 | 1005 | 5 | 28 | 33 | 101.4 |

| 1000 | 1016 | 1230 | 1022 | 34 | 1160 | 92 | 1071 | 10 | 1110 | 5 | 28 | 36 | 119.7 |

Check available Sizes of Blind Raised Face Flanges, Ask For Ready Stock of Blind Flange, ASME/ ANSI B16.5 BLRF Flanges in Mumbai, India.

BAGODA

Quick ContactReady Stock Blind Flanges

- Inconel Blind Flange

- 1/2 Blind Flanges

- ANSI B16.5 Blind Plate Flanges

- DIN Standard PN25 Blind Flanges

- Class 600 Blind Flange

- ANSI B16.5 Class 1500 Blind Flange

- BS4504 Large Diameter Blind Flange

- EN 1092-1 Blind Flange

- High Nickel Alloy Series A and B RTJ Blind Flange

- Monel Raised Face Blind Flange

- AWWA C207 Class D Raised Face Blind Flange

- 254 SMO Blind Flanges Stockist

- Super Duplex 2507 BLRF Flanges

- ASME B16.5 Blind Flange Class 400

- Copper Nickel BLFF Flanges

- ASME B16.5 Blind Flange Exporter

- Copper Nickel Raised Face Blind Flange Distributor

- BLFF Flanges Manufacturer

- Class 75 Blind Plate Flange

- Brass Blind Flange

- Duplex Steel 2205 Blind Flange

- Blind Flanges Manufacturer

- JIS B2220 5K 10K 16K Blind Flanges

- ASME B16.47 Blind Flange

- Carbon Steel BLRTJ Flanges

- ANSI B16.5 Blind Flanges

- BS4504 PN16 Blind Flange

- ANSI #150 Blind Flanges

- Class 600 BLRF Flange

- Blind 8 Inch Flanges

- DIN 2605 BLFF Flanges

- API 6A BLRF Flange

- JIS 16K Blind Flange

- Brass Blind Raised Face Flanges

- A182 Blind Raised Face Flanges

- Alloy 20 Blind Plate Flanges Supplier in Mumbai

- ASME B16.5 Hastelloy Blind Raised Face Flanges

- Titanium Blind Flange

- ASME B16.5 Blind Plate Flanges

- Blind Plate Flanges Stockholder

- High Quality BLRTJ Flanges

- JIS 10K Blind Flange

- Titanium Blind Flanges Manufacturer

- PN25 Blind Flange