UNS K11572 Weldolet, Grade F11 Alloy Threadolet, Alloy Steel F11 Sweepolet Stockist, Alloy Steel F11 Nipple Outlets, CrMo F11 Flexolet, Alloy Steel F11 Branch Outlet Fittings, 1.7335 Latrolet, Chrome Moly F11 Branch Connection Fittings, Alloy Steel F11 Bran Outlet Fittings Supplier in Mumbai, India.

Because of its advanced excessive - temperature strength and fabrication abilities, it's far the go-to steel for extraordinarily combustive applications and additives which includes business furnaces and flame holders, chemical processing, and fueloline turbine engineering. The excessive - temperature is a matrix stiffened nickel – chromium – molybdenum – iron alloy with cobalt and tungsten additions. Alloy Steel F11 Threading Outlet has first-rate resistance to a huge style of chemical method environments, which includes robust oxidizers which include ferric and cupric chlorides, chlorine, formic and acetic acids, warm infected media (natural and inorganic), acetic anhydride, seawater and brine solutions. In addition, it resists formation of grain boundary precipitates within the weld warmness affected region making it beneficial for maximum chemical approaches within the as - welded situation.

It is frequently utilized in Bleach flowers and digesters for the producing of paper and pulp, Marine engineering, Components used round bitter fueloline, Pollution control, Waste treatment, and so on. It isn't susceptible to grain boundary precipitation within the as welded situation and consequently appropriate for plenty chemical method applications. Also, Alloy Steel F11 Socket Weld Outlet has first-rate resistance to phosphoric acid in any respect temperatures beneath boiling and at decrease concentrations. It reveals excessive resistance to chloride - triggered pitting and crevice attack, types of corrosion to which the austenitic stainless steels are specifically prone. It can perform from cryogenic temperatures as much as 750 Degree F (four hundred Degree C).

Material Specification Chart of Alloy Steel F11 Olets

| Specifications | ASTM A182/ ASME SA182 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Alloy Steel F11 Olets Manufacturing Standards

| ASTM A182/A182M | Wrought Austenitic Alloy Steel F11 Outlet Fittings |

|---|---|

| ASME SA182 – ASTM A182 | Standard Specification for Wrought Austenitic Alloy Steel F11 Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM A182 – ASME SA182 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of Alloy Steel F11 Olets

- Alloy Steel F11 Welding Outlet

- Grade F11 Alloy Weldolet

- Cr-Mo A182 F11 Weldolet

- 1.7335 Welding Outlet

- UNS K11572 Weldolet

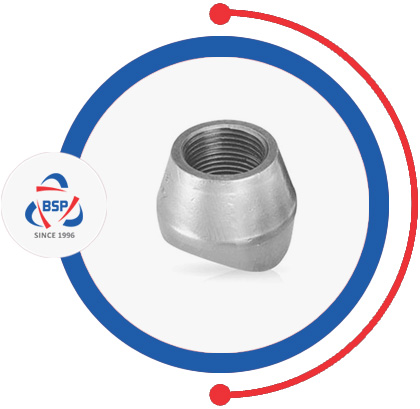

- Chrome Moly F11 Threading Outlet

- UNS K11572 Threaded Outlet

- 1.7335 Threadolet

- Alloy Steel F11 Threadolet

- Alloy Steel F11 Threadolet

- CrMo F11 Socket Weld Outlets

- F11 Alloy Steel Sockolet

- 1.7335 Sockolet

- UNS K11572 Sockolet

- Alloy Steel F11 Socket Weld Olets

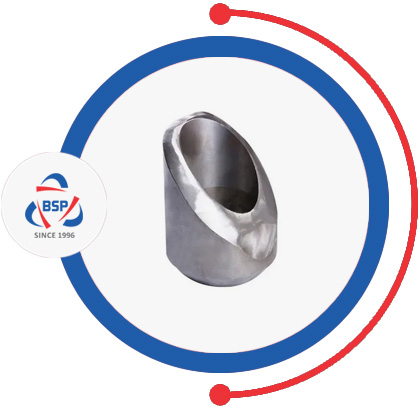

- Alloy Steel F11 Elbolet

- Chrome Moly F11 Elbow Outlets

- 1.7335 Elbolet

- UNS K11572 Elbolet

- 1.7335 Latrolet

- F11 Alloy Steel Lateral Outlet

- UNS K11572 Latrolet

- Alloy Steel F11 Latrolet

- Cr-Mo A182 F11 Nipple Outlets

- UNS K11572 Nippolet

- 1.7335 Nippolet

- Alloy Steel F11 Nippolet

- 1.7335 Flexolet

- Alloy Steel F11 Flexolet

- UNS K11572 Flexolet

- Chrome Moly F11 Flexolet

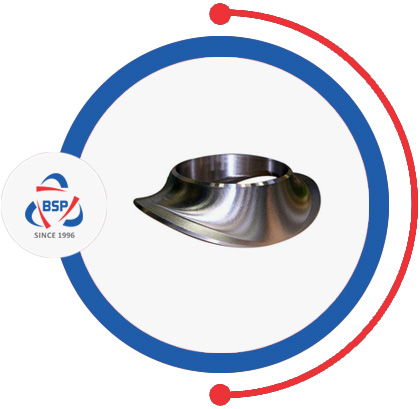

- UNS K11572 Sweepolet

- Grade F11 Alloy Sweepolet

- 1.7335 Sweepolet

- Alloy Steel F11 Swept Outlet

- Alloy Steel F11 Brazolet

- F11 CrMo Brazolet

- 1.7335 Brazolet

- UNS K11572 Brazolet

- Alloy Steel F11 Flangeolet

- CrMo F11 Flangeolet

- UNS K11572 Flangeolet

- 1.7335 Flangeolet

- 1.7335 Coupolet

- Alloy Steel F11 Coupolet

- UNS K11572 Coupolet

- Cr-Mo A182 F11 Coupolet

- UNS K11572 Insert Weld Outlet

- Chrome Moly F11 Insert Weld Outlet

- 1.7335 Insert Weld Outlet

- Alloy Steel F11 Insert Weld Outlet

Equivalent Grades of Alloy Steel F11 Insert Weld Outlet

- Alloy Steel F11 Weldolet Distributor

- F11 Alloy Steel4 Branch Connection

- F11 Alloy Steel Sweepolet

- Alloy Steel F11 Threading Outlet

- DIN 1.7335 Socket Weld Outlets

- F11 Alloy Steel Industrial Olets

- ASTM A182 Alloy Steel F11 Olets Branch Fittings

- F11 Alloy Steel Threading Outlet

- UNS K11572 Olet Fittings

- ASTM A182 Alloy Steel F11 Flexible Outlet

- CrMo F11 Olets Manufacturer

- 5" Nb Grade F11 Alloy Elbolet

- F11 Alloy Steel Sockolet

- Chrome Moly F11 Flangeolet

- Alloy Steel F11 Olets

- Alloy Steel F11 Nippolet

- F11 Alloy Steel Nipple Outlet Exporter

- Cr-Mo A182 F11 Branch Outlets Fittings

- CrMo F11 Latrolet

- Alloy Steel F11 Coupolet

- ASME SA182 Alloy Steel F11 Threadolet

- Chrome Moly F11 Outlet Fittings

- Alloy Steel Fl Coupling Outlet

- F11 CrMo Outlets

- Grade F11 Alloy Insertweldolet

- F11 CrMo Welding Outlets

- F11 Alloy Stee Pipe Outlets

- Alloy Steel F11 Insert Welding Outlet Manufacturer

- Cr-Mo A182 F11 Brazolet Supplier in Mumbai

- Alloy Steel F11 Olet Fittings

- ASTM A182 Alloy Steel F11 Flexolet

- CrMo F11 Olet Fittings

| STANDARD | WERKSTOFF NR. | UNS | EN | DIN |

| A182 F11 | 1.7335 | K11572 | 1.1/4Cr-1/2Mo | 13CRM044 |

View Thickness Table Of Alloy Steel F11 Olets, We have Global sales network for Grade F11 Alloy Outlet Connection Fittings, Wide Stockist Of Werkstoff No 1.7335 Socket Weld Outlets In India.

Check available Sizes of ASME SA 182 Alloy Steel F11 Branch Outlets Fittings, Ask For Ready Stock of UNS K11572 Threadolets in Mumbai, India.

BAGODA

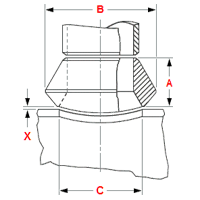

Quick ContactAlloy Steel F11 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

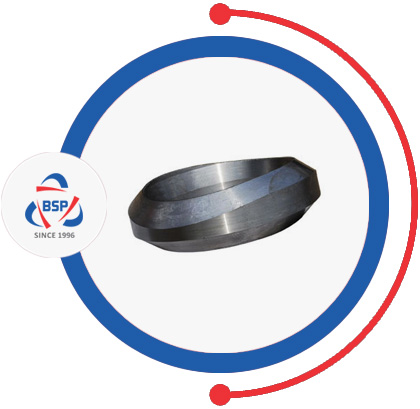

Alloy Steel F11 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Alloy Steel F11 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F11 Nipolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F11 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F11 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Alloy Steel F11 Olets

Alloy Steel F11 Olets Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F11 | 0.15 max | 0.3-0.6 | 0.5 - 1 | 0.03 | 0.03 | 1 - 1.5 | 0.044 - 0.65 |

Alloy Steel F11 Olets Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| A182 F11 | 205 | 415 | 20 |