UNS S32109 Flanges, DIN 1.4878 SORF Flanges, SS 321H RTJ Flanges Supplier in Mumbai, India.

Once the metallic is worked and ready, the batch is reduce to suit order requirements. The maximum not unusual techniques are mechanical techniques, which include reducing with guillotine knives, round knives, excessive-velocity blades or punching with dies. However, for complicated shapes, flame reducing or plasma jet reducing can be used as well. Common strategies encompass acid or sand etching, sand blasting, belt grinding, belt buffing and belt polishing. At this point, Stainless Steel WNR 1.4878 Weld Neck Flanges is accrued in its very last shape and readied for transport to the customer.

They are not unusual place approaches to each save and deliver huge portions of stainless to be used in different production processes. However, the very last shape will rely upon the sort of metallic required and different elements precise to the order. At present, a huge variety of industries utilize chrome steel. Aside from conventional and marine constructions, family home equipment also is experiencing an upward thrust in usage. While 321H Stainless Steel Reducing Flanges is extra luxurious than slight metallic, its excellent properties cause accelerated carrier lifestyles and decreased cycle cost. So the bigger in advance fees repay within the longer run. They are proof against corrosion thru the addition of alloying elements.

Material Specification Chart of SS 321H Flanges

| Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

SS 321H Flanges Manufacturing Standards

| American Standard | Standard Code | ANSI ASME SA-182 | ANSI ASME B16.5 | ASME – B 16.47 | ASME – B 16.36 | ||

|---|---|---|---|---|---|---|---|

| Standard Name | Forged Flanges | Slip on flange, Welding neck flange, Blind flange, Threaded flange, Lap joint flange, RTJ flange | Welding neck flange, Blind flange | Welding neck flange Slip on flange | |||

| German Standard | DIN 2527 | DIN 2573 / 2576 | DIN 2673 | DIN 2641 / 2642 | DIN 28115 | DIN PN10, PN16 | DIN PN20, PN25 |

| Steel Blind Flanges, BLRF | Flat Flange for Welding (Slip On) | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) | Lapped / Loose (Lap Joint) Flanges Plain Collars | Long Neck Welding Flanges | PN10 Flanges, DIN PN 10 Flanges, PN16 Flange | PN20 Flanges, DIN PN 25 Flanges | |

| Japanese Standard | JIS B2220 | JIS B2291 | JIS 5K, 10K | JIS 16K, 20K | JIS 30K, 40K | ||

| Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | 5K SORF Flanges, 10K SOFF Flanges | 16K Blind Flanges, 20K BLRF Flanges | 30K Slip on Flanges, 40K Blind Flanges | |||

| Italian Standard | UNI FLANGES | ||||||

| Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) | |||||||

| British Standard | BS 10 Table D | BS 10 Table E | BS 10 Table F | BS 10 Table H | |||

| BS 10 Table D Flanges, Table D Pipe Flange | BS 10 Table E Flanges, Table E Pipe Flange | BS 10 Table E Flanges, Table E Flanges | BS 10 Table E Flanges, Table E Pipe Flanges |

Manufacturing Standards / Pressure Rating

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

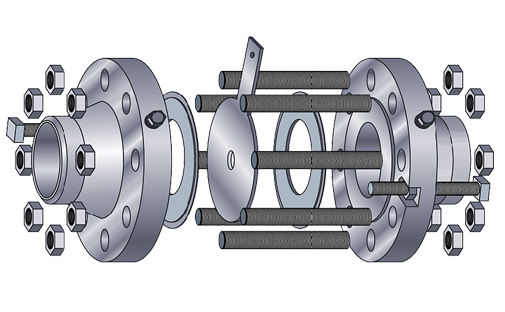

Various Types Of 321H Stainless Steel Flanges

- Stainless Steel 321H SWRF Flanges

- 321H SS Socket weld Flanges

- ASTM A182 SS 321H Socket weld Flanges

- UNS S32109 Socket weld Flanges

- 1.4878 Socket weld Flange

- ASME SA182 SS 321H SWRF Flanges

- Stainless Steel 321H LJ Flanges

- 321H SS Lapped Joint Flanges

- ASTM A182 SS 321H Lap Joint Flanges

- UNS S32109 Lap Joint Flanges

- 1.4878 Lap Joint Flange

- ASME SA182 SS 321H Lapped Joint Flanges

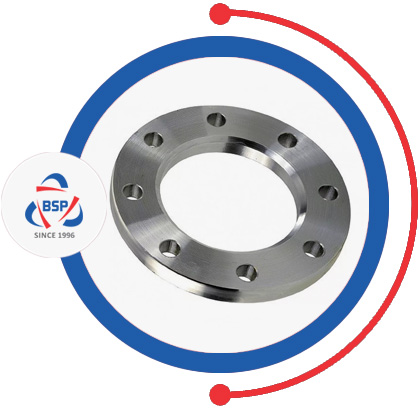

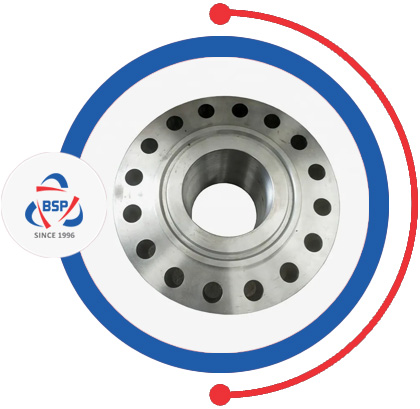

- Stainless Steel 321H SORF Flanges

- 321H SS Slip on Flanges

- ASTM A182 SS 321H Slip on Flanges

- UNS S32109 Slip on Flanges

- 1.4878 Slip on Flange

- ASME SA182 SS 321H SORF Flanges

- Stainless Steel 321H Forged Flanges

- 321H SS Forged Flanges

- ASTM A182 SS 321H Forged Flanges

- UNS S32109 Forged Flanges

- 1.4878 Forged Flange

- ASME SA182 SS 321H Forged Flanges

- Stainless Steel 321H Orifice Flanges

- 321H SS Orifice Flanges

- ASTM A182 SS 321H Orifice Flanges

- UNS S32109 Orifice Flanges

- 1.4878 Orifice Flange

- ASME SA182 SS 321H Orifice Flanges

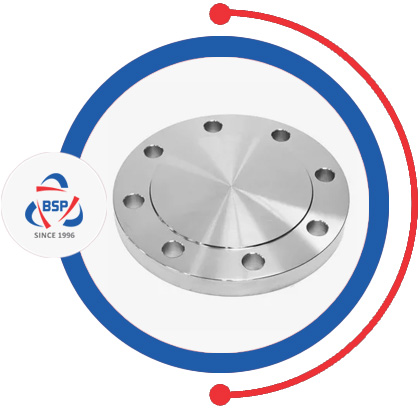

- Stainless Steel 321H BLRF Flanges

- 321H SS Blind Flanges

- ASTM A182 SS 321H Blind Flanges

- UNS S32109 Blind Flanges

- 1.4436 Blind Flange

- ASME SA182 SS 321H BLRF Flanges

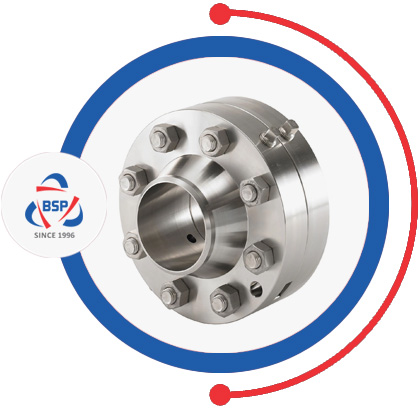

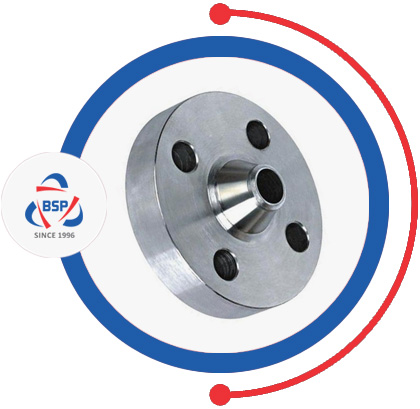

- Stainless Steel 321H WNRF Flanges

- 321H SS Welding Neck Flanges

- ASTM A182 SS 321H Weld Neck Flanges

- UNS S32109 Weld Neck Flanges

- 1.4436 Welding Neck Flange

- ASME SA182 SS 321H WNRF Flanges

- Stainless Steel 321H Reducing Flanges

- 321H SS Reducing Flanges

- ASTM A182 SS 321H Reducing Flanges

- UNS S32109 Reducing Flanges

- 1.4878 Reducing Flange

- ASME SA182 SS 321H Reducing Flanges

- Stainless Steel 321H Threaded Flanges

- 321H SS Screwed Flanges

- ASTM A182 SS 321H Threaded Flanges

- UNS S32109 Threaded Flanges

- 1.4878 Threaded Flange

- ASME SA182 SS 321H Screwed Flanges

- Stainless Steel 321H LWN Flanges

- 321H SS Long Weld Neck Flanges

- ASTM A182 SS 321H Long Weld Neck Flanges

- UNS S32109 Long Weld Neck Flanges

- 1.4878 Long Weld Neck Flange

- ASME SA182 SS 321H LWN Flanges

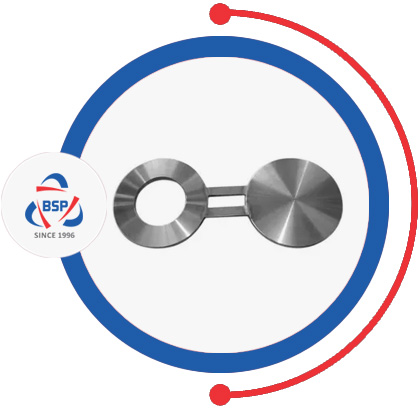

- Stainless Steel 321H Spectacle Blind Flanges

- 321H SS Spectacle Blind Flanges

- ASTM A182 SS 321H Spectacle Blind Flanges

- UNS S32109 Spectacle Blind Flanges

- 1.4878 Spectacle Blind Flange

- ASME SA182 SS 321H Spectacle Blind Flanges

- Stainless Steel 321H RTJ Flanges

- 321H SS Ring Type Joint Flanges

- ASTM A182 SS 321H RTJ Flanges

- UNS S32109 Ring Type Joint Flanges

- 1.4878 Ring Type Joint Flange

- ASME SA182 SS 321H RTJ Flanges

Equivalent Grades of Stainless Steel 321H Flanges

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| SS 321H | S32109 | 1.4878 | SUS 321H | X12CrNiTi18-9 |

View Size Table Of 321H SS Pipe Flanges, We have Global sales network for Stainless Steel 321H SORF Flanges, Wide Stockist Of Werkstoff No 1.4878 BLRF Flanges, Raised Face, Flat Face Flanges In India.

Check available Sizes of ASME SA 182 F321H Pipe Flanges, Ask For Ready Stock of UNS S32109 Male & Female Flanges in Mumbai, India.

BAGODA

Quick ContactSchedule / Class of Stainless Steel 321H Flanges

| Flange Schedule/Class | Flange Connection Type | Pipe Size – Pipe Flanges | Max. Pressure |

|---|---|---|---|

| ASME B16.5 Class 150 | FNPT | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 1/2″ | 275 psi |

| ASME B16.5 Class 150 | Welded | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | FNPT | 3/4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 3/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 1-1/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 1-1/2″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | 2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 2-1/2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 3″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | 4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 4″ | 275 psi |

| ASME B16.5 Class 300 | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | FNPT | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 4″ | 720 psi |

Pressure Rating Of 321H Stainless Steel Flanges

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 321H | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 321H | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 321H | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Size Chart Of Stainless Steel 321H Flange

| Nominal Pipe Size | Outside Diameter of Flanges | Thickness of Flanges | Diameter of Raised Face | Diameter of Hub at Base | Length Thru Hub | Diameter or Bore | Diameter of Hub at Bevel | Radius of Fillet | Depth of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding Neck | Slip-On Threaded Socket | Lap Joint | Slip-on Socket | Lap Joint | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Weight Chart Of Stainless Steel 321H Flanges

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

| 1/2" | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2" | 0.4 | 0.9 |

| 3/4" | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2" | 0.7 | 1.5 |

| 1" | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2" | 0.8 | 1.8 |

| 1-1/4" | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2" | 1.2 | 2.6 |

| 1-1/2" | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2" | 1.5 | 3.3 |

| 2" | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8" | 2.3 | 5.1 |

| 2-1/2" | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8" | 3.7 | 8.1 |

| 3" | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8" | 4.1 | 9 |

| 3-1/2" | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8" | 5.1 | 11.2 |

| 4" | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8" | 5.9 | 13 |

| 5" | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4" | 7 | 15.4 |

| 6" | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4" | 8.4 | 18.5 |

| 8" | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4" | 13 | 28.6 |

| 10" | 250 | 406.50 | 30.20 | 321H.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8" | 18 | 39.5 |

| 12" | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8" | 29 | 64 |

| 14" | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1" | 39 | 86 |

| 16" | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1" | 47 | 103 |

| 18" | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8" | 57 | 126 |

| 20" | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8" | 76 | 167 |

| 24" | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4" | 97 | 214 |

Ready Stock Stainless Steel 321H Flanges

- Stainless Steel 321H EN 1092-1 Flange

- Stainless Steel 321H JIS B2220 Flange

- AISI 321H Flanges

- SS 321H Slip On Flanges Distributor

- SS 321H Long Weld Neck Flanges

- Stainless Steel 321H BLRF Flange

- Stainless Steel 321H Screwed Flanges

- Stainless Steel 321H Large Diameter Flanges

- 321H Stainless Steel Flanges Manufacturer

- ANSI B16.5 Stainless Steel 321H PN16 Flanges

- 321H SS RTJ Flanges Manufacturer

- Stainless Steel 321H Loose Flanges

- 321H Stainless Steel DN150 PN16 Flange

- ASME B16.5 Stainless Steel 321H Slip on Flanges

- ASTM A180 F321H Expander Flanges

- Stainless Steel 321H Welding Neck Flanges

- ANSI B16.5 SS 321H Male & Female Flanges

- 321H SS AWWA C207 Flange Stockist

- 321H SS JIS B2220 Flange

- 6 Inch 321H Stainless Steel Pipe Flanges

- ASTM A182 Stainless Steel 321H Plate Flanges

- SS 321H Lapped Joint Flanges

- 321H Stainless Steel Square Flanges

- DIN 1.4878 Pipe Flanges

- ASTM A182 F321H SORF Flange

- 3 inch SS 321H Welding Neck 300 LBS Flange

- Stainless Steel 321H Ring Type Joint Flanges

- UNS S32109 Flanges

- 1.4878 SWRF Flange

- Stainless Steel 321H Raised Face Flanges Exporter

- 321H Stainless Steel Flat Flanges

- 321H SS Blind Flange

- Stainless Steel 321H Orifice Flanges

- SS 321H DIN 2566 PN10 Flanges Stockholder

- 321H SS Blind Flanges Supplier in Mumbai

- Stainless Steel 321H BS 4504 Flanges

- 321H SS High Hub Blind Flanges

- SS 321H Reducing Flanges

- Stainless Steel 321H Paddle Spacer Flanges

- 321H Stainless Steel Lap Joint Flanges

- Stainless Steel 321H WNRF Flange

- 321H Stainless Steel Pipe Flanges

- 321H Stainless Steel Threaded Flanges

- SS 321H BLRF Flange

- Stainless Steel SUS 321H Class 2500 Flange

- ASTM A182 F321H Socket weld Flanges

- ASME SA182 F321H Stainless Steel Forged Flanges

- ASME B16.5 Stainless Steel Spectacle Blind Flanges

- Stainless Steel 321H Tongue & Groove Flanges

- Class 150 321H Stainless Steel Pipe Flange

- SS 321H BS 4504 Flanges

- SS 321H JIS B2220 Flange

Stainless Steel 321H Flanges Chemical Composition

| % | Cr | Ni | C | Si | Mn | P | S | N | Ti | Fe | |||||

| 321H | min:17.0 max:19.0 |

min: 9.0 max:12.0 |

min:0.04 max:0.10 |

min:18.0 max:20.0 |

max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N) max:0.70 | Balance |

321H Stainless Steel Flanges Mechanical Properties

| Grade | Tensile Strengtd ksi (min.) |

Yield Strengtd 0.2% Offset ksi (min.) |

Elongation - % in 50 mm (min.) |

Hardness (Brinell) MAX |

| 321H/321HH | 75 | 30 | 40 | 217 |